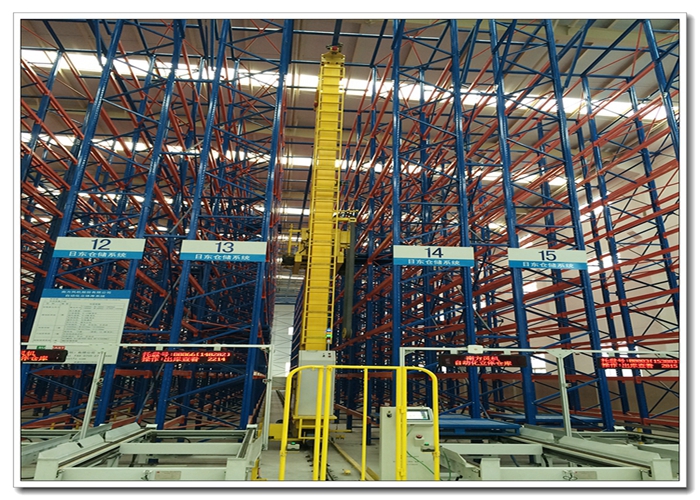

Warehouse Automated Storage and Retrieval System Heavy Duty ASRS System

Products' components Description

1. Racking

Racking system used for AS/RS usually consists of pallet racking and cantilever racking, treated with powder coated, dismantled structure.

Advantages of Racking System

1. Optimized sectional design, quality steel used.

2. Pitch is adjustable by 75mm for uprights, and beams are tightly locked by safety pins.

3. Strengthened by quality bolt&nut, safe and reliable.

4. Perfect structure, high intensity, good stability.

5. Good looking with epoxy powder coated surface.

2. Storage&Retrieval System

Normally we have 2 kinds of such equipment, the Stacker Crane and Shuttle Carrier.

Operational control mode: Computer monitoring & controlling system and PLC detecting system to get automatic control system achieved.

Operator Schema: Online automatic mode, single-computer automatic mode, semi-automatic mode, manual mode, maintenance mode.

Automatic addressing modes: Laser-measuring addressing, rolling addressing, barcode addressing.

Communication modes: infrared communication, wireless communication.

3. Conveyor System

Conveying system is include by various of conveyor system, lifting & transferring device, lift, various shuttle, detecting door, computer monitoring system, automated control system.

Tge operation of commodity arrival, unloading, sorting, storage, shipment, classification, issuing, is bound to go through the transport sorting equipment in different levels of complexity to realized unloading and sorting according to the product type, owner, storage or sending location in the shortest possible time, also delivered to the designated positions(such as the designated shelves, processing areas, shipping platform, ect. )

Meanwhile, when the supplier or the owner notify the logistics center to make the shipment according to the distribution instructions, automated sorting system must accurately find out the location of the goods which need to be shipped from the giant high-level storage system in the shortest time and delivery as per requred quantity.

It also picks different quantity of goods from different storage positions, delivering to different tally area or distribution platform based on different on different delivery locations, making an easy transportation or loading distribution, fully realizing a rapid delivery sorting funcion.

4. Controlling system

Structural feature:

Communicating with WMS and ECS through OPC agreement, PROFIBUS bus network, set up by SIEMENS S7-300 controller can operate all conveyors offline, doing conveying of goods automatically.

Please refer to the attached drawing for details of conveying system

5. WMS System

Hardwares of WMS System: star network structure, network sever, RF server, computers for management and monitor, RF base station and RF terminal for in/out warehouse of goods.

Softwares of WMS System:

Operating system: WINDOW 2000X SEVER

Data-base: MS SQL SEVER 2000X

Warehouse management software: WMS

Equipment controlling software: ECS

Bar code management software: RFS

6. Other related equipment

Other related equipment include switching cart, rail cart, O/R table, automatic guided vehicle, auto-picking system, electronic label, pallet lift and so on.

3)Products' Advantage

1. Can fully use the warehouse space/height

2. Saving space

3. Reducing the labor cost

4. Reduce the error rate due to manual operation

5. Improving working and management etc.

4)More pictures about this products

5)If any enquiry, please contact:

cindy@gzwangu.com